Kimberly Adams Russell is taking over the role from her father, David Adams, marking the third generation to hold the title.

T.I.A., Part 2: Visiting Small-Scale Mines in Kenya

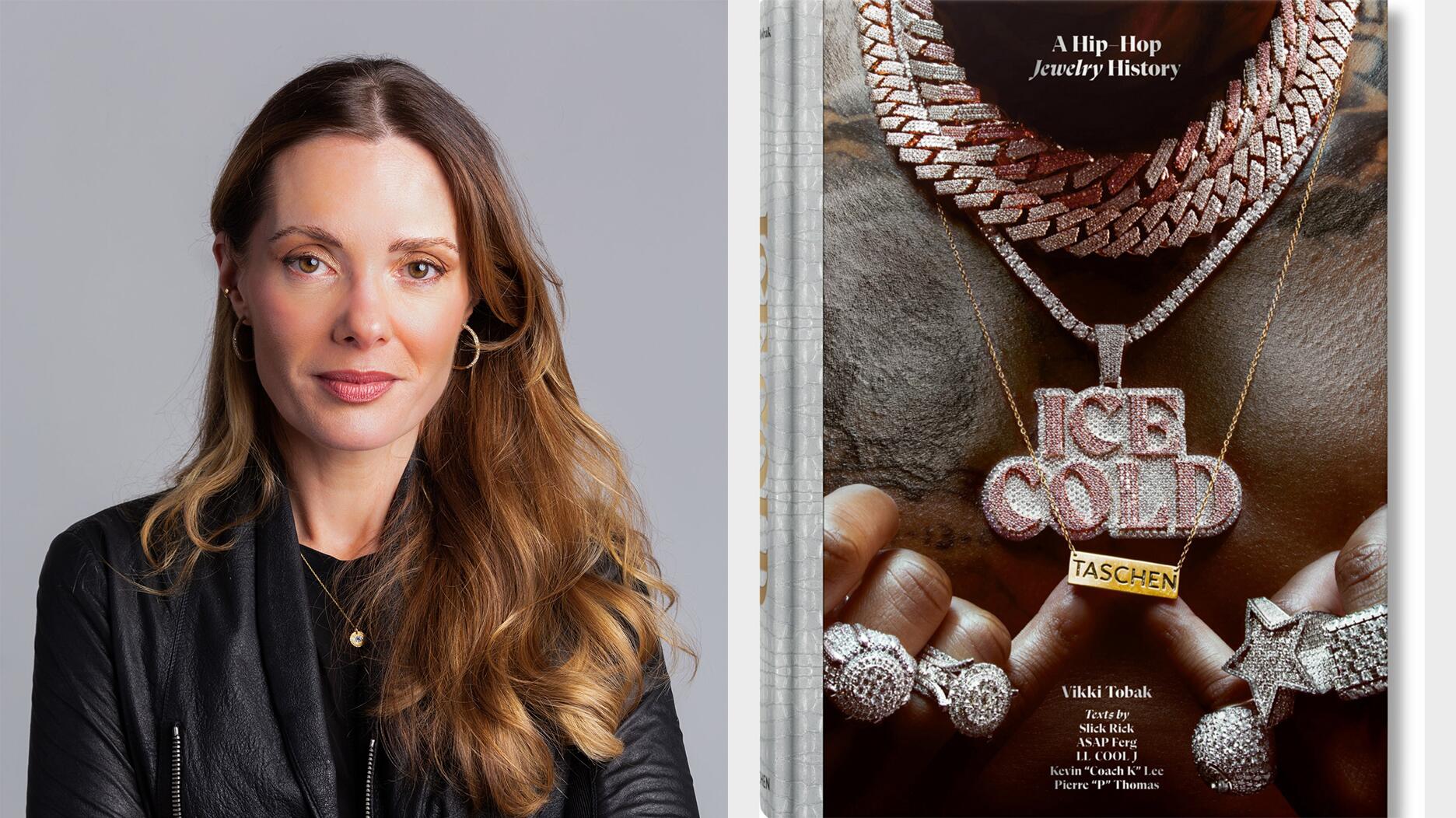

In the second installment of a multi-part series about her trip to East Africa, Associate Editor Brecken Branstrator talks about her experience visiting two mines in southern Kenya.

I see finished jewelry pieces all the time. I also frequently meet designers, the faces behind the brands, manufacturers and retailers. What I hadn’t seen were the early stages of the process; I’m talking from the point where miners are digging through the earth to find a stone and everything through the purchase of the rough, the cutting and polishing, and on to when it’s ready to be set in jewelry.

My first blog post about my African adventures detailed my experience looking through rough material with two gemstone cutters.

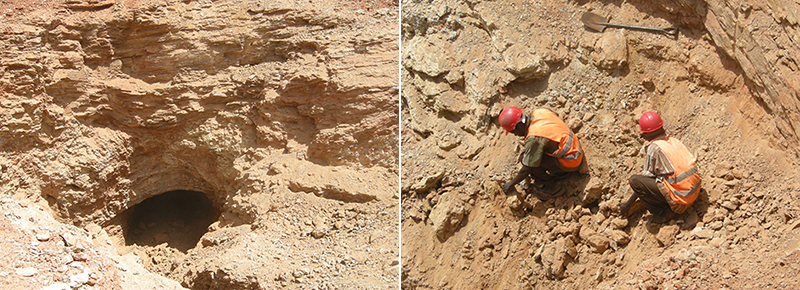

While we were in Kenya, we also got to visit two small-scale, and very different, mining sites.

The first was a cooperative mining area called Chawia Minerals Community Based Organization (CBO). The closest town to it is Mikuki, Kenya, and it produces tsavorite garnet and green and yellow tourmaline.

Currently, there are approximately 220 miners registered with CBO, one owner told me. They have been allocated their own mining pits, and each pit could have several people working it.

Registering with the CBO for the ability to mine costs KSh 5,000 (a little under $50). When the mine owners or their workers find something, they have to take the stone(s) to one of the CBO owners, who values it. Once the price is approved the mine owner pays the CBO owners a portion of that value. They can pay in cash or in gemstones.

The benefit of a cooperative system like this is that it allows more people to have access to mining who might not have been able to afford to buy a site on their own.

While the site is working to promote the local mining community, CBO Chairman Gabriel Mcharo said what they really need is not only investors to help grow the operation but also technology to aid in the mining activity.

I would then see exactly what he meant.

As we walked over to a mine, I noticed a few “steps” that had been carved into the side of the hill (this is pictured in the image on the right in the above set) that allowed for a way to clear out the tailings from the mine.

There were men standing on one step each, all the way down and then into the mining tunnel. The process was slow—workers inside the mine would dig with a shovel and then toss the pile of gravel on to the next man, who would pick it up with his shovel, toss it up to the next, and so it would go out of the mine and up the hill, one by one, to clear it out.

It seemed like such tedious work, I couldn’t imagine how long it would take to make any sort of significant headway. This is the kind of thing that really makes you think about a gemstone differently—knowing the effort that goes into pulling it out of the ground.

The next day, we went to the mine of gem dealer and broker Gichuchu Okeno, which is about a three-hour drive outside of Voi, Kenya.

I briefly mentioned Okeno in my first blog post in the “T.I.A.” series, but that introduction didn’t do him justice. Okeno already seems to be having a big impact on the Kenyan gemstone market, and I can tell he’s going to keep changing it for the better.

Okeno operates his own mine in a very secluded part of southern Kenya. Our Land Cruiser had to go over some very bumpy terrain to get there (picture hours of unpaved road), but the drive was worth it.

His is different from many of the other artisanal mines in that he is not only putting safety first, enforcing regulations such as making the workers wear helmets and fluorescent vests, but he also constructed brand-new housing and a place to cook so the miners can live in better conditions on site.

Okeno also scheduled it so that they would be blasting while we were there, so I got to witness (from a safe distance, of course) them blast away a part of the land as they redirected their digging according to what a geologist told them.

The blast brought up a lot of the vein that they were following, so a few of the workers and Okeno talked us through which pieces indicated that they were going in the right direction to, hopefully, unearth some gemstones.

I sincerely hope it proves fruitful for them soon.

Stay tuned for the next blog post from my trip, highlighting recent announcements from Kenya and Tanzania about keeping gem cutting in-country and what’s being done to try to build that market.

The Latest

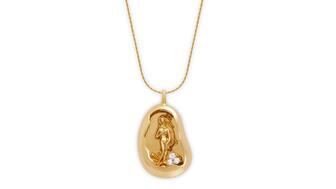

As a token of womanhood, this necklace depicts when Venus was born from the sea.

The deal gives the retailer control over the distribution of Roberto Coin jewelry in the U.S., Canada, Caribbean, and Central America.

Tradeshow risks are real. Get tips to protect yourself before, during and after and gain safety and security awareness for your business.

Show your mother some love with a piece of fine jewelry.

The company’s Easton location will remain open.

Brian D. Fleming of Carla Corporation was elected to serve a one-year term in the role.

Meet Ben Claus—grand prize winner of For the Love of Jewelers 2023 Fall Design Challenge.

Sponsored by the Las Vegas Antique Jewelry and Watch Show

M.S. Rau is set to open a seasonal gallery in the high-end resort town early next month.

The branded jewelry market is thriving, said Richemont Chairman Johann Rupert.

The six designers, all participants in the show’s Diversity Action Council mentorship program, will exhibit in Salon 634.

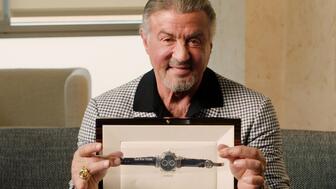

The highlight of his collection is the coveted Patek Philippe Grandmaster Chime, which could sell for up to $5 million.

The “Venetian Link” series modernizes the classic Veneziana box chain in its bracelets and necklaces.

The Seymour & Evelyn Holtzman Bench Scholarship will provide tuition assistance to two low-income students.

The Swiss watchmaker said the company’s plans to use a new version of the Hallmark crown on jewelry would confuse consumers.

The executive talked about the importance of self-purchasers and how fuel cell electric vehicles are going to fuel demand for platinum.

The Indian jeweler’s new store in Naperville, Illinois marks its 350th location, part of its ongoing global expansion plans.

It will award a graduating high school student with about $10,000 toward a GIA diploma and an internship with the Seattle-based jeweler.

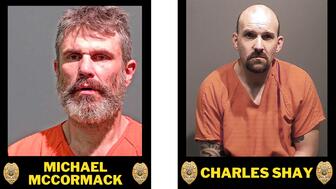

Wheat Ridge, Colorado police took a 50-year-old man into custody Wednesday following a two-month search.

PGI partnered with four new and seven returning designers for its annual platinum capsule collection.

Nicolosi, president and CEO of The Kingswood Company, previously sat on WJA’s board from 2011 to 2018.

Karina Brez’s race-ready piece is a sophisticated nod to the horse-rider relationship.

The men are allegedly responsible for stealing millions in jewelry and other valuables in 43 burglaries in 25 towns across Massachusetts.

“Horizon” invites individuals to explore the limitless possibilities that lie ahead, said the brand.

The jeweler credits its recent “Be Love” campaign and ongoing brand revamp for its 17 percent jump in sales.

The co-founder of Lewis Jewelers was also the longtime mayor of the city of Moore.