The medals feature a split-texture design highlighting the fact that the 2026 Olympics are taking place in two different cities.

Gemfields Opens $15M Automated Sort House in Mozambique

The colored stone miner said the state-of-the-art facility will significantly raise production levels.

London—Gemfields has opened a $15 million ruby sort house at its Montepuez ruby mine in Mozambique.

The colored stone miner said the state-of-the-art facility will significantly raise production levels, allowing it to “consistently deliver a greater volume and spectrum” of rubies.

It uses the natural properties of rubies as a means for automated sorting, Gemfields said.

The raw material is first washed and then passed under ultraviolet light. Since rubies naturally fluoresce under UV light, optical sorters can detect the fluorescence and then use blasts of air to direct individual rubies to separate channels for further sorting and grading.

Gemfields said using programmable logic controllers and data software under the UV light is faster, more reliable and more efficient than the human eye. It also allows for the identification of a finer material component than before.

The facility also accommodates more wash plants, now washing the equivalent of 10,000 tons of ore per day.

“Previously the sorting of rubies was largely manual, but it is very exciting to now introduce automated sorting, which will require minimal manual sorting,” said Kaung San, the company’s ruby grading supervisor. “Our productive capacity will increase exponentially.”

Gemfields said the automation of the sorting process won’t result in a reduction in its workforce.

In fact, increased productivity at the sort house means Gemfields will expand its current active mining area, requiring the company to hire more people.

The colored stone miner also said the manual aspect of the sorting process—the categorization and grading of the rubies—will require more highly skilled employees. Rather than look outside the country for this expertise, Montepuez is training a group of Mozambican gemologists who will specialize in the selection and classification of rubies.

Gemfields said its $15 million investment in the sort house is the largest of its kind in the Cabo Delgado province of Mozambique.

Looking ahead, the colored stone miner said the new sort house will be complemented by the addition of a new thickener to the wash plant this year, increasing capacity from 125 tons per hour to 150 tons per hour.

Two high-capacity pre-screen plants also will be added to remove the finer particle material prior to being fed to the wash plant, resulting in a greater concentration of material of the desired size.

The Latest

From tech platforms to candy companies, here’s how some of the highest-ranking brands earned their spot on the list.

The “Khol” ring, our Piece of the Week, transforms the traditional Indian Khol drum into playful jewelry through hand-carved lapis.

Launched in 2023, the program will help the passing of knowledge between generations and alleviate the shortage of bench jewelers.

The catalog includes more than 100 styles of stock, pre-printed, and custom tags and labels, as well as bar code technology products.

The chocolatier is bringing back its chocolate-inspired locket, offering sets of two to celebrate “perfect pairs.”

The top lot of the year was a 1930s Cartier tiara owned by Nancy, Viscountess Astor, which sold for $1.2 million in London last summer.

Criminals are using cell jammers to disable alarms, but new technology like JamAlert™ can stop them.

The Swiss watchmaker has brought its latest immersive boutique to Atlanta, a city it described as “an epicenter of music and storytelling.”

In his new column, Smith advises playing to your successor's strengths and resisting the urge to become a backseat driver.

The index fell to its lowest level since May 2014 amid concerns about the present and the future.

The new store in Aspen, Colorado, takes inspiration from a stately library for its intimate yet elevated interior design.

The brands’ high jewelry collections performed especially well last year despite a challenging environment.

The collection marks the first time GemFair’s artisanal diamonds will be brought directly to consumers.

The initial charts are for blue, teal, and green material, each grouped into three charts categorized as good, fine, and extra fine.

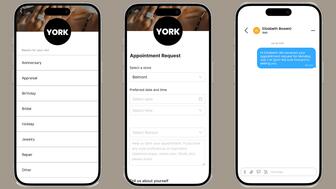

The new tool can assign the appropriate associate based on the client or appointment type and automate personalized text message follow-ups.

Buyers are expected to gravitate toward gemstones that have a little something special, just like last year.

Endiama and Sodiam will contribute money to the marketing of natural diamonds as new members of the Natural Diamond Council.

The retailer operates more than 450 boutiques across 45 states, according to its website.

The new members’ skills span communications, business development, advocacy, and industry leadership.

The jeweler’s 2026 Valentine’s Day campaign, “Celebrating Love Stories Since 1837,” includes a short firm starring actress Adria Arjona.

The new features include interactive flashcards and scenario-based roleplay with AI tools.

Family-owned jewelry and watch retailer Deutsch & Deutsch has stores in El Paso, Laredo, McAllen, and Victoria.

The Italian luxury company purchased the nearly 200-year-old Swiss watch brand from Richemont.

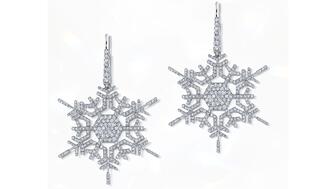

Micro-set with hundreds of diamonds, these snowflake earrings recreate “winter’s most elegant silhouette,” and are our Piece of the Week.

Ella Blum was appointed to the newly created role.

Sponsored by RapNet