From tech platforms to candy companies, here’s how some of the highest-ranking brands earned their spot on the list.

GIA Finds Imitation Emerald Made of Layered Glass

The 3.35-carat stone had a natural beryl core; glass layers were attached to it with a “colorless cement.”

New York—Another gem has surfaced at a lab that was not entirely what it seemed.

A 3.35-carat “emerald” submitted to the Gemological Institute of America’s New York lab turned out to be an assembled imitation gemstone composed of five layers of glass cemented to a beryl core, according to an article by Tyler Smith and Augusto Castillo in the Summer 2018 issue of Gems & Gemology.

The rectangular core was a natural beryl, the mineral species to which emerald belongs, but the crown was a single piece of glass attached to the pavilion, while the pavilion was composed of four asymmetrical glass segments glued to the core using a “colorless cement.”

The imitation stone probably took a while to create using a “laborious multistep cut-and-glue process,” GIA authors said, as indicated by the way the four glass segments in the pavilion are interlocked.

The manufacturing of the piece started by attaching a glass segment to the beryl core. Both were then cut to create a flat surface for a second piece of glass. The second was then added, cut to allow for the third, and so forth.

After all four had been added, the assembled pavilion likely would have been polished flat to allow for the crown, which then would have been attached.

(Check out the original lab note from GIA for a diagram showing the process.)

The article also noted that while assemblages of various materials have long been used to imitate precious stones—with the most common kind using two or more pieces joined together in parallel, layered fashions—GIA researchers weren’t able to find record of another stone assembled using the process applied to this “emerald.”

RELATED CONTENT: Glued-Together Diamond Turns Up at GIAGIA said it was the first time one such assembled stone has been submitted to its New York or Carlsbad laboratories.

Researchers surmise that the imitation emerald was created relatively recently, given the fact that all its exposed surfaces are made of glass and, yet, the facet junctions are still sharp and the stone lacks wear.

“It is intriguing that an antiquated technique is updated in modern times, serving as a cautionary tale of the ingenuity counterfeiters employ,” the authors said.

The Latest

The “Khol” ring, our Piece of the Week, transforms the traditional Indian Khol drum into playful jewelry through hand-carved lapis.

The catalog includes more than 100 styles of stock, pre-printed, and custom tags and labels, as well as bar code technology products.

Launched in 2023, the program will help the passing of knowledge between generations and alleviate the shortage of bench jewelers.

The chocolatier is bringing back its chocolate-inspired locket, offering sets of two to celebrate “perfect pairs.”

The top lot of the year was a 1930s Cartier tiara owned by Nancy, Viscountess Astor, which sold for $1.2 million in London last summer.

Any gemstones on Stuller.com that were sourced by an AGTA vendor member will now bear the association’s logo.

Criminals are using cell jammers to disable alarms, but new technology like JamAlert™ can stop them.

The Swiss watchmaker has brought its latest immersive boutique to Atlanta, a city it described as “an epicenter of music and storytelling.”

The new addition will feature finished jewelry created using “consciously sourced” gemstones.

In his new column, Smith advises playing to your successor's strengths and resisting the urge to become a backseat driver.

The index fell to its lowest level since May 2014 amid concerns about the present and the future.

The new store in Aspen, Colorado, takes inspiration from a stately library for its intimate yet elevated interior design.

The brands’ high jewelry collections performed especially well last year despite a challenging environment.

The collection marks the first time GemFair’s artisanal diamonds will be brought directly to consumers.

The initial charts are for blue, teal, and green material, each grouped into three charts categorized as good, fine, and extra fine.

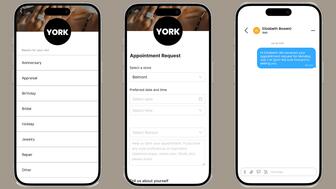

The new tool can assign the appropriate associate based on the client or appointment type and automate personalized text message follow-ups.

Buyers are expected to gravitate toward gemstones that have a little something special, just like last year.

Endiama and Sodiam will contribute money to the marketing of natural diamonds as new members of the Natural Diamond Council.

The retailer operates more than 450 boutiques across 45 states, according to its website.

The new members’ skills span communications, business development, advocacy, and industry leadership.

The jeweler’s 2026 Valentine’s Day campaign, “Celebrating Love Stories Since 1837,” includes a short firm starring actress Adria Arjona.

Family-owned jewelry and watch retailer Deutsch & Deutsch has stores in El Paso, Laredo, McAllen, and Victoria.

The Italian luxury company purchased the nearly 200-year-old Swiss watch brand from Richemont.

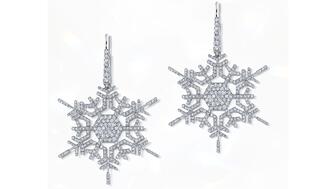

Micro-set with hundreds of diamonds, these snowflake earrings recreate “winter’s most elegant silhouette,” and are our Piece of the Week.

Ella Blum was appointed to the newly created role.

Sponsored by RapNet